Material boost for all-plastic 5G dipole antennas

沙特基础工业公司推出了poly-sulfide塑料材料for 5G base station dipole antennas and other electronic applications.

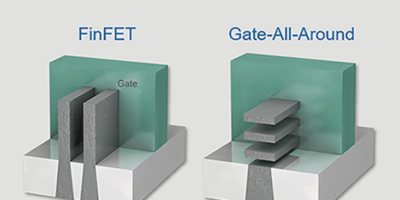

的现况Thermocomp OFC08V化合物使lightweight, cost-effective, all-plastic antenna designs for the deployment of 5G infrastructure. This is a glass fibre-reinforced material based on polyphenylene sulfide (PPS) resin with excellent plating performance using laser direct structuring (LDS), strong layer adhesion, good warpage control, high heat resistance, and stable dielectric and RF performance. This combination of properties could enable an injection moldable new dipole antenna design, offering advantages over traditional printed circuit board (PCB) assembly and the selective electroplating of plastic.

The material has previously been used for 3D molded electronics:Liquid crystal polymers for 3D interconnect in 5G designs

The key for an all-plastic antenna is the metal plating using LDS. The material offers a wide laser processing window and both ease of plating and uniformity in plating line width to help ensure stable and consistent antenna performance. Strong adhesion between the plastic and metal layers avoids delamination, even following thermal aging and lead-free reflow soldering. Improved dimensional stability and lower warpage compared to competitive glass-reinforced PPS grades help achieve smooth fixation of the metal plating during LDS, as well as accurate assembly.

After injection molding of the part, LDS only requires laser structuring and chemical plating. In addition, the material provides all the performance benefits of glass-filled PPS, including high heat resistance for PCB assembly using surface mount technology, and inherent flame retardancy (UL-94 V0 at 0.8 mm). Low dielectric values (dielectric constant: 4.0; dissipation factor: 0.0045) and stable dielectric performance, together with good RF performance under harsh conditions, help optimize transmission and extend useful life.

As a result the compound has been listed by LPKF Laser & Electronics, a German provider of laser manufacturing solutions, as an approved thermoplastic for LDS with the company’s systems.

+MORE