Starting all over again on plastic: ARM

And to better put things in perspective, celebrating the 25th anniversary of the company’s founding, Muller had set to pick 2um design rules to build a small SoC around a Cortex M0 and exhibit the result to the conference attendees.

"You don’t put many SoCs on a six-inch wafer at the 2um node", he said, showing a nearly transparent sheet with about 5 or 6 "dies", each holding the Cortex M0 and enough memory and enough I/Os to boot and make an LED flash. But as Muller flexed the wafer back and forth, he revealed the Cortex M0 blocks had been built on a sheet of plastic, using plastic transistors instead of silicon.

ARM’s CTO Mike Muller showing plastic SoCs.

"It’s pretty slow, it’s nMOS, we haven’t got to CMOS yet, so its power dissipation is not the best, but it’s about the thickness of cling film" Muller added, hinting that such designs could be used to run very low power IoT applications integrated into packaging.

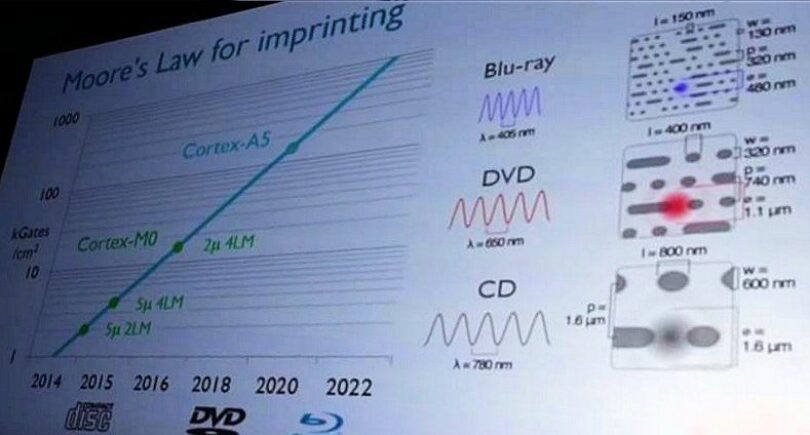

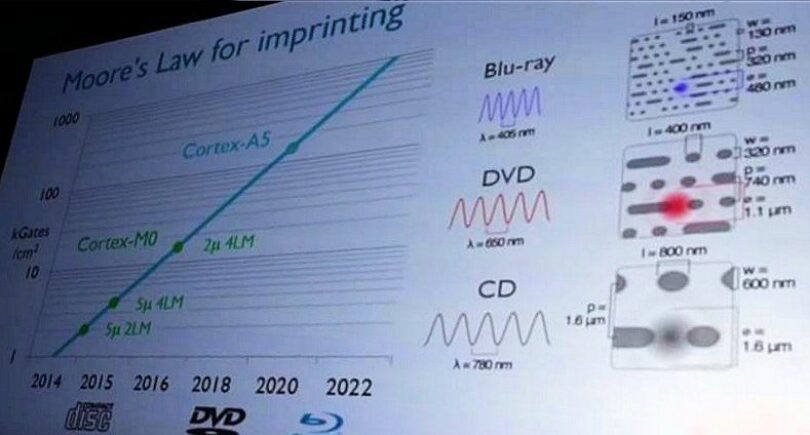

The CTO then shared his expectations of Moore’s law for imprint technology, the technology used to implement these circuits in plastic, establishing a parallel with the move from CDs, to DVDs to Blu-Ray as finer imprint resolutions are achieved. The roadmap read as if a Cortex-A5 would be next in line by 2020 with sub-micron design rules.

+MORE